What is a Wedge Wire Screen?

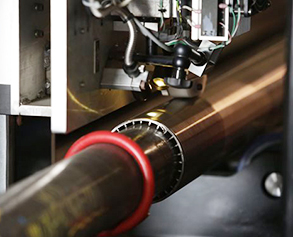

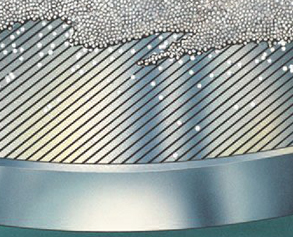

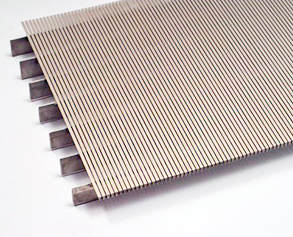

Wedge wire screens are produced by resistance welding V-shaped wire on support rods. We use the highest quality raw wire to weld our wedge wire screens, and we can cut, shaped, fabricated the screens to get a harf finished or full finished screen product for our customers.

YMX Filters can offer wedge wire screens as raw screen material, like the pipes, bends, and flat panels, and we can also fabricated the screen to a finished product to suite your application requirements. The pin point control over the specifications of the slot is what allows us to provide our customers with highly accurate flow distribution and effective media, debris and sediment filtration. Supporting Rods running perpendicular to the wrap wire strengthen and maintain the proper design configuration of the screen allowing it to handle intense pressure demands.

Our Wedge Wire Screen is designed to control various processing conditions including volumetric flow rate, minimum dimensional media retention, minimum open area and fluid pressure capabilities. YMX FILTER is able to professionally work a large variety of stainless steels and alloys into both standard or customizable screen applications and accessory products.

The benefits of using wedge wire:

Extended lifetime

Slot during abrasive operation on the screen surface does not change

Capability to withstand heavy loads

High open area

Less prone to clogging

Perfectly smooth and flat surface

High precision of execution Increased capacity and more precise separation

Self-cleaning effect

Low pressure loss

Increased efficiency

Permanence of exploited resources

Lower capital cost and maintenance

Wedge Wire Screen Diameter

Screen diameters range from 0.750” to 38”, and up to 48” diameters in fabricated sections.

Your specific tolerance and size requirements will be adhered to and meet the required industry standards. By designing and building our screen machines we can assure ourselves of the best possible attention to detail, thereby the finest finished product.

We provide custom engineered and fabricated filtration equipment such to meet all our customers’ filtration needs which includes: Sub Arc, Tig, Mig and Stick welding capabilities and many other machines such as water jet, lathe etc. These capabilities greatly reduce manufacturing time and allow us to provide fast delivery of our products.

What Makes Wedge Wire Perfect for Fine Straining and Filtering?

The features of stainless steel wedge wire contribute to their ideal functionality in fine straining and filtering. The design of wedge wire ensures no clogging will occur; giving you an uninterrupted flow. This cuts out downtime and increases production. Likewise, the screens on the wedge wire are welded into ladder-like patterns that make backwashing easy, while also increasing the safety and reliability of the product.

Wedge wire also has a continuous slot opening. This is important because this type of opening dramatically increases the open area that is available. This, in turn, gives a greater access to the water-bearing zone, so more water-based products can be filtered at one time with this type of wire screen.

As you can see, stainless steel wedge wire is an ideal product for a variety of industrial needs. To recap, here are some highlights of wedge wire.

It has fine filtering capabilities, more so than most other wedge wire screen filters on the market.

It is built to be durable and safe to use in most industrial settings.

It can be made a custom size for the individual client.

It can be combined with various configurations of support rods for custom projects.

It has a wide range of industrial uses in several different industries where straining and filtering to a fine degree is of utmost importance.

When you need a wedge wire screen filter that does extremely fine straining of particles of virtually any shape.

YMX FILTER MANUFACTURING CO., LTD

Wedge Wire Screen

Wedge Wire Screen  Wedge Wire Screen

Wedge Wire Screen  Wedge Wire Screen

Wedge Wire Screen  Wedge Wire Screen

Wedge Wire Screen

The Industrial applications for Stainless Steel Wedge Wire?

Wedge wire screen panels have a number of excellent industrial uses. While they can be used for any custom need of a client, the top industrial uses include:

Filtering foods that require a high level of purity, such as soups, chocolate, and cold-pressed juices.

Filtering oil or other viscous products.

Removing solids from brewing products, such as bottled teas and microbrew beers (both alcoholic and non-alcoholic).

Separating animal feed before distributing it to livestock.

Separating manure in the fertilizer industry.

Removing solids from wastewater.

Separating solids from dirt in mineral mining and processing.