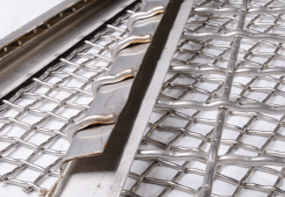

Woven Wire Cloth is also known as woven wire mesh, is woven on looms, shares a similar process that applied to the ones used to weave clothing. Metal wires are woven together to produce wire mesh cloth. The Woven wire mesh weaved by heavier wire gauges and larger opening sizes are called the Crimp Wire Cloth. And the woven mesh weaved by thinner wires, especially the ones used for filtration screens are called Fine Woven Cloth.

YMX Filter’s Woven Wire Cloth is produced on special wire weaving machines. A wide range of materials is used for manufacturing the mesh. The range of materials for metal meshes extends from non-alloyed steel to non-ferrous metal such as copper, bronze, brass, nickel, nickel-based alloys and high-alloy stainless steels through to titanium and precious metals. Depending on the material and weave type, porous media with a much wider range of uses than textile meshes can be produced.

The woven wire cloth also differs significantly from high-performance textiles: thanks to the mechanical capability, temperature resistance, conductivity and the versatile possibilities of metal processing. In the field of architecture, the meshes are also coated, painted, blastedand anodized.

The applications of the woven cloth are based on this fact that the meshes are always ideal media with precisely defined and reproducible pore sizes. They are therefore predestined for separation and filtration technology. At the same time, the even structures open up many application options in the field of architecture making versatile use of the combination of regularity, transparency and visual appearance.

In addition to the visual impact of metal meshes, the functional advantages in the field of architecture are also convincing, for example as an air-permeable exterior shell of multi-story car parks or stadiums. The structural properties of the mesh allow for an optimal combination of design and function in many applications: Sun protection, sound absorption for false ceilings, safety functions through roller shutters and railings or LED-equipped transparent media with metal mesh as the carrier material.

The remarkable strength and versatility of woven wire mesh make it an excellent choice for numerous applications,include:

Fine Woven Cloth Crimp Wire Cloth

Application of fine woven cloth: Application of Crimp Wire Cloth

Filtration and separation Separation

Sifting and sizing Sifting and Sizing

Air and water filters Architectural decoration

Waste water treatment Fencing and gates

Fuel screen Grills and Baskets

Mud screen Display shelves and stands

Diamond screen Wire racks

Separator screen Wall reinforcement

Cathode screen Infill for fence panels

Raw material for filters and strainers Window Screens

Oil filters, fuel filters, hydraulic filters Glare control

Process screen Ventilation fan screens

Centrifuge screen Handrails and safety guards

Pest control and livestock cages

With innovative mesh technologies and the latest simulation methods, YMX FILTERS has developed and produced efficient technical weaves, semi-finished products, components and filter equipment – optimally matched to the most diverse mechanical process engineering requirements. We use our high-level laboratory expertise to continually refine and further optimize our products. Leading manufacturing standards, certified processes and comprehensive testing procedures secure end-to-end high quality in filter cloth materials. This approach allows us to produce some of the most reliable, high-performance filter media in the world. Our innovative capacity, many years of experience with application processes and customer proximity, coupled with our cost-focused and user-centered approach, have made YMX FILTERS the first choice international partner for industrial mesh.

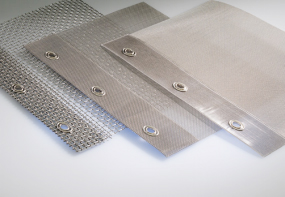

Fine Woven Wire Cloth

The fine woven wire clothes are produced on looms as mesh rolls, mainly used in filtration industry. The meshes are stored in rolls. All further processing steps are then performed on the basis of this roll material.

The mesh rolls are used as a semi-finished product in applications where it is logistically undesirable to supply the material as strips or cut-to-size pieces due to the many different dimensional requirements.

Standard roll lengths range between 30 and 50 m. Depending on the mesh used, however, lengths of up to 300 m can be supplied.

Mesh rolls can be cleaned up to a width of 2 m and thermally treated up to a maximum width of 1 m.

If meshes are required in smaller widths, partial widths can be produced from a mesh roll and ultimately become mesh strips.

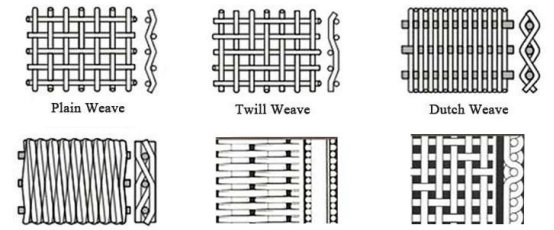

Weaving Types of Woven Cloth

Woven wire clothes are weaved in different patterns, such as PLAIN WEAVE, TWILL WEAVE, PLAIN DUTCH WEAVE, TWILL DUTCH WEAVE, REVERSE PLAIN DUTCH WEAVE, REVERSE TWILL DUTCH WEAVE, FIVE-HEDDLE WEAVE.

Plain Square Woven Wire

The most common weave type, with the same diameter warp and shute wires woven in a simple over and under pattern. It produces screens with the same mesh count in both directions.

Twill Square Woven Wire

Each shute wire typically passes over two warp wires and under two, producing square openings. Twill weave can be made from larger-diameter wires than would be possible in plain square weave to obtain greater strength, density or corrosion resistance.

Plain Dutch Woven Wire

Woven in a plain, over and under pattern. A thinner, smaller diameter shute wire is used; these are driven very close together creating a very tight weave. Dutch weaves do not have a straight-through, clear opening as do most plain weave styles. Instead the weave style creates a tortuous path through which very fine filtration and particle retention can be achieved. Dutch weaves may be specified by "mesh count" or "absolute filter rating."

This extremely tight mesh is ideally suited for filtration applications, as well as the separation of slurry and liquid materials.

Dutch Twill Weave

Similar to Plain Dutch except woven in the Twill style. Each wire passes over two wires then under two wires, still utilizing a smaller-diameter shute wire, allowing an even tighter weave and even finer filtration than Plain Dutch weave.

Twilled Dutch weave is capable of filtering materials as fine as two microns in diameter, making it well-suited for various liquid and gas applications.

Reverse Dutch Weave

The same weave as Plain Dutch except the warp and shute wires are reversed; the warp wires have a smaller diameter than the shute wires. The larger shute wires are woven closer together than would usually be seen in a Plain Dutch weave.

Reverse plain Dutch weave is ideally suited for solid filtration applications where maintaining mechanical stability is of primary importance, such as those involving heavy-duty cleaning processes, centrifugal filter cake removal or back washing.

Five Heddle Weave

Five heddle weave provides a rectangular opening. The unique design of this mesh can assist increased drainage and flow properties. This mesh also has a smooth surface on one side, which is widely used in filtration of petroleum chemical industries, in the form of filter ribbons and filter elements.

Five heddle weave offers high flow rates and is suitable for high mechanical loads, featuring a lightly structured mesh surface. Five-heddle woven meshes are popular in applications including pressure and vacuum filters as well as filter candles.

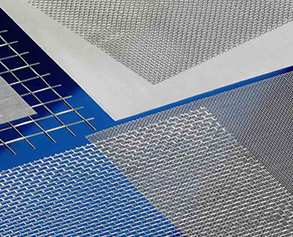

Woven wire is available on the roll or cut to size

YMX supply woven wire cloth both in rolls and custom cut sized strips.It is always identified with labels showing the material description, mesh and aperture or wire diameter, dimensions and number of pieces, if applicable. Standard roll lengths are 1m wide 30 meters long, or 1.22m wide 30 meters long. A limited number of woven wire cloth are available up to 2m wide.

These are always available in stainless steel and in some specifications, plain and galvanised steel. Other metals and special alloys are generally made to order - please contact us with your special requirements.

Stocking roll woven wire cloth

SS Plain and Twill Weave Mesh Specifications

| Meshes per Linear inch | Wire diameter | Width of opening | Open area | ||

| inch | mm | inch | mm | percent | |

| 1×1 | .157 | 4.0 | .84 | 21.4 | 71.0 |

| 2×2 | .118 | 2.5 | .38 | 10.2 | 64.0 |

| 3×3 | .079 | 2.0 | .25 | 6.4 | 58.0 |

| 4×4 | .063 | 1.6 | .187 | 4.75 | 56.0 |

| 4×4 | .047 | 1.19 | .203 | 5.16 | 65.9 |

| 5×5 | .055 | 1.4 | .14 | 3.68 | 52.0 |

| 6×6 | .047 | 1.2 | .12 | 3.03 | 51.0 |

| 8×8 | 0.43 | 1.1 | .08 | 2.08 | 42.0 |

| 10×10 | .039 | 1.0 | .06 | 1.54 | 36.0 |

| 10×10 | .020 | .51 | .080 | 2.03 | 64.0 |

| 12×12 | .023 | .584 | .060 | 1.52 | 51.8 |

| 12×12 | .020 | .508 | .063 | 1.60 | 57.2 |

| 14×14 | .023 | .584 | .048 | 1.22 | 45.2 |

| 14×14 | .020 | .508 | .051 | 1.30 | 51.0 |

| 16×16 | .018 | .457 | .0445 | 1.13 | 50.7 |

| 18×18 | .017 | .432 | .0386 | .98 | 48.3 |

| 20×20 | .020 | .508 | .0300 | .76 | 36.0 |

| 20×20 | .016 | .406 | .0340 | .86 | 46.2 |

| 24×24 | .014 | .356 | .0277 | .70 | 44.2 |

| 30×30 | .013 | .330 | .0203 | .52 | 37.1 |

| 30×30 | .012 | .305 | .0213 | .54 | 40.8 |

| 30×30 | .009 | .229 | .0243 | .62 | 53.1 |

| 35×35 | .011 | .279 | .0176 | .45 | 37.9 |

| 40×40 | .010 | .254 | .0150 | .38 | 36.0 |

| 50×50 | .009 | .229 | .0110 | .28 | 30.3 |

| 50×50 | .008 | .203 | .0120 | .31 | 36.0 |

| 60×60 | .0075 | .191 | .0092 | .23 | 30.5 |

| 60×60 | .007 | .178 | .0097 | .25 | 33.9 |

| 70×70 | .0065 | .165 | .0078 | .20 | 29.8 |

| 80×80 | .0065 | .165 | .0060 | .15 | 23.0 |

| 80×80 | .0055 | .140 | .0070 | .18 | 31.4 |

| 90×90 | .005 | .127 | .0061 | .16 | 30.1 |

| 100×100 | .0045 | .114 | .0055 | .14 | 30.3 |

| 100×100 | .004 | .102 | .0060 | .15 | 36.0 |

| 100×100 | .0035 | .089 | .0065 | .17 | 42.3 |

| 110×110 | .0040 | .1016 | .0051 | .1295 | 30.7 |

| 120×120 | .0037 | .0940 | .0046 | .1168 | 30.7 |

| 150×150 | .0026 | .0060 | .0041 | .1041 | 37.4 |

| 160×160 | .0025 | .0635 | .0038 | .0965 | 36.4 |

| 180×180 | .0023 | .0584 | .0033 | .0838 | 34.7 |

| 200×200 | .0021 | .0533 | .0029 | .0737 | 33.6 |

| 250×250 | .0016 | .0406 | .0024 | .0610 | 36.0 |

| 270×270 | .0016 | .0406 | .0021 | .0533 | 32.2 |

| 300×300 | .0015 | .0381 | .0018 | .0457 | 29.7 |

| 325×325 | .0014 | .0356 | .0017 | .0432 | 30.0 |

| 400×400 | .0010 | .0254 | .0015 | .0370 | 36.0 |

| 500×500 | .0010 | .0254 | .0010 | .0254 | 25.0 |

| 635×635 | .0008 | .0203 | .0008 | .0203 | 25.0 |

SS PLAIN DUTCH WEAVE SPECIFICATIONS

| Mesh count per inch | Wire diameter inches | Absolute filter rating microns | Nominal filter rating microns |

| 8×85 | 014×.0126 | 318-340 | 250-255 |

| 12×64 | .024×.0165 | 270-285 | 200-205 |

| 14×88 | .020×.013 | 225-245 | 150-155 |

| 20×150 | .0098×.007 | 155-165 | 100-105 |

| 24×100 | .015×.010 | 115-125 | 80-85 |

| 30×150 | .009×.007 | 95-100 | 65-70 |

| 40×200 | .007×.0055 | 65-70 | 55-60 |

| 50×250 | .0055×.0045 | 55-60 | 40-45 |

| 80×400 | .0049×.0028 | 43-48 | 35-40 |

SS TWILL DUTCH WEAVE SPECIFICATIONS

| Mesh count per inch | Wire diameter inches | Absolute filter rating microns | Nominal filter rating microns |

| 20×250 | .0098×.0079 | 110-120 | 98-105 |

| 30×360 | .0098×.0060 | 90-100 | 80-84 |

| 40×560 | .0070×.0040 | 70-75 | 47-52 |

| 80×700 | .0040×.0030 | 35-40 | 24-26 |

| 200×600 | .0024×.0018 | 28-32 | 19-21 |

| 165×800 | .0028×.0020 | 24-26 | 14-16 |

| 165×1400 | .0028×.0016 | 16-18 | 9-11 |

| 200×1400 | .0028×.0016 | 12-14 | 5-6 |

| 250×1400 | .0022×.0016 | 11-12 | 3-4 |

| 325×2300 | .0015×.0010 | 8-9 | 2-3 |

| 400x2800 | .0011x.0008 | 5-6 |

SS REVERSE DUCTH WEAVE WIRE CLOTH SPECIFICATIONS

| YMX-code | Mesh | Wire diameter(um) | Micron Retention(um) | Prosity Theory (%) | Weight (kg/m2) | Cloth Thickness (mm) | |||

| Warp | Weft | Nominal | Absolute | ||||||

| RFD400 | 84×14 | - | - | - | 450-530 | 62 | 3.5 | 1.15 | |

| RFD125 | 260×40 | - | - | 125 | 112-125 | 54 | 2.25 | 0.62 | |

| RFD90 | 170×40 | - | - | 90 | 106-118 | 54 | 2.1 | 0.57 | |

| RFD85 | 175×37 | - | - | 85 | 100-106 | 54 | 2.1 | 0.57 | |

| RFD80 | 130×30-35 | 200 | 380 | 80 | 95-105 | 57 | 2.7-3.10 | .77-.80 | |

| RFD60 | 175×40-50 | 150 | 300 | 60 | 65-72 | 55 | 2.1-2.40 | .57-.60 | |

| RFD40 | 280×60-70 | 90 | 200 | 40 | 54-60 | 56 | 1.34-1.55 | .38-.40 | |

| RFD25 | 600×100-105 | 42 | 140 | 25 | 34-38 | 57 | .75-.80 | .22-.23 | |

| RFD20 | 630×125-130 | 42 | 125 | 17 | 22-26 | 53 | .75-.85 | .20-.22 | |

| RFD15 | 720×140-150 | 35 | 110 | 15 | 16-20 | 52 | .65-.70 | .15-.18 | |

YMX FILTER MANUFACTURING CO., LTD

Woven Cloth

Woven Cloth  Woven Cloth

Woven Cloth  Woven Cloth

Woven Cloth  Woven Cloth

Woven Cloth

YXM FILTERS is known as a customer-focused metal screen company that is willing to do whatever it takes to achieve total customer satisfaction. Fast turnaround times are our specialty – we understand the importance of keeping your projects on schedule, and we make every effort to deliver our products as quickly and efficiently as possible.

Contact us for more information and a free quote today.

We are available 24/7. Call us at 0086-18931635571

Or email us to get a fast reply: info@ymxfilter.com