We are a wire screen supplier.How much do you know about wire mesh?

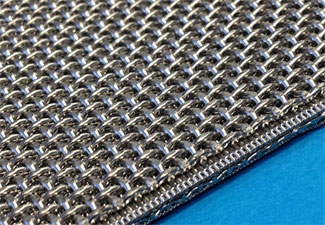

Wire screen is used as the support of screen printing plate, commonly known as silk screen, silk screen, yarn screen, screen, etc. Screen printing commonly used screen has natural screen, synthetic screen, metal screen, special screen and so on. The performance number of screen, such as material, mesh number, opening degree and opening rate, has a great influence on the transfer of screen printing ink. According to different reproduction originals, choosing the appropriate screen is the premise of obtaining high-quality screen printing reproduction.

Metal screen filler is a kind of high efficiency filler widely used in the world. Its main advantages are as follows:

The number of theoretical plates is high, the flux is large and the pressure is low;

The load performance is good, the number of theoretical plates increases with the decrease of gas load, and there is almost no low load limit;

Large flexibility of operation;

The amplification effect is not clear;

It can meet the requirements of precision, large-scale and high vacuum distillation unit. It provides favorable conditions for distillation separation of difficult separation system, heat sensitive system and high purity products.

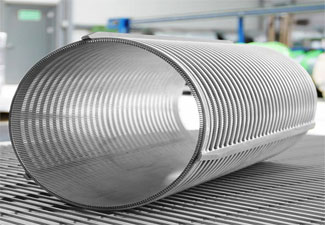

Mesh packing is the main form of mesh corrugated packing, which is made of metal mesh. The pressure of corrugated metal wire mesh packing is reduced and the separation efficiency is very high. It is especially suitable for precision distillation and vacuum distillation devices. It provides an effective means for distillation of difficult separation and heat sensitive systems. Despite its high cost, it has been widely used because of its excellent performance.

The advantages of wire mesh corrugated packing are compact structure, small resistance, high mass transfer efficiency, large processing capacity and large specific surface area (commonly used are 125, 150, 250, 350, 500, 700, etc.). The disadvantage of wire mesh packing is that it is not suitable for handling materials with high viscosity, easy polymerization or suspended solids.

Corrugated packing has the advantages of good cooling effect, small resistance, light capacity, high strength, fire resistance and corrosion resistance. It is widely used in hyperbola, natural draft tower, mechanical tower, cement frame cooling tower, cross flow cooling tower and counter flow cooling tower. High efficiency of mass transfer requires a large gas-liquid contact surface. That is to say, it is required to have a large specific surface area, and the filler surface is easy to be wetted by liquid. Only wetted surfaces are gas liquid contact surfaces. Large production capacity and small gas pressure drop.

Therefore, it is required that the void ratio of the packing layer is large. Non displacement causes bias and channeling. Durable with good corrosion resistance, high mechanical strength and necessary heat resistance.