Custom metal screen supplier to share this article for you.

Filtration refers to a unit operation that separates solid matter particles suspended in a gas or liquid. A porous material is used to pass the gas or liquid in the suspension, and the retained solid particles remain on the filter medium to form a filter cake. Filtration operations are widely used in various chemical productions, especially for separating solid particles in liquids, as well as dust for gas separation, such as bag filters.

The industrial filter is a kind of filter, widely used in metallurgy, chemical industry, petroleum, papermaking, medicine, food, mining, electric power, urban water supply. Such as industrial wastewater, circulating water filtration, emulsion regeneration, waste oil filtration treatment, continuous casting water system in the metallurgical industry, blast furnace water system, high-pressure water descaling system for hot rolling. It is an advanced, efficient, and easy to operate automatic filtering device.

In general, the mixture to be filtered is called a filter slurry, the clear liquid passing through the filter medium is called a filtrate, and the layer of solid particles that are trapped is called a filter cake.

The filtration of the gas-solid mixture is generally carried out under the effect of a pressure difference. The purpose of the filtering operation is sometimes to obtain a clarified fluid, such as the filtration of lubricating oil or air; sometimes to obtain suspended solid particles, such as separating the crystal product from the mother liquor during crystallization;

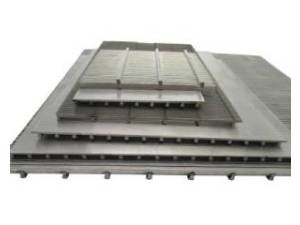

Wedge Wire Screen

According to the driving force of the process, filtration methods can be divided into:

① Gravity filtration, the driving force of operation is the static pressure of the liquid column of the suspension itself, generally not exceeding 50kPa, this method is only applicable to the treatment of filter slurry with large particle size and low content;

②Pressurized filtration, pressurizing the filtered slurry with a pump or other methods can produce higher operating pressure, generally up to 500kPa or more, and can effectively handle filter slurry that is difficult to separate;

③ Vacuum filtration, a vacuum is drawn on the bottom side of the filter medium, and the pressure difference generated usually does not exceed 85kPa, which is suitable for filter pulp containing mineral particles or crystal particles and is convenient for washing the filter cake;

④ Centrifugal filtration, the operating pressure is the centrifugal force generated by the filter layer, which is convenient for washing the filter cake, and the resulting filter cake has less liquid content, and is suitable for the filtration of crystal materials and fiber materials.

There are many types of filtration equipment. Machines that implement gravity filtration, pressure filtration, and vacuum filtration are generally called filter machines; machines that perform centrifugal filtration are called centrifugal filter machines.

The mechanism can be divided into surface filtration and deep filtration according to the mechanism of the filter media intercepting solid particles. The former is widely used in chemical production; the latter is rarely used.

The core component of the filtration equipment is the filter screen filter core. How to select the most suitable filter core is a key step.

In the filtration of the industrial industry, the most common, most durable, and reliable filter core is the wedge wire filter screen.

The stainless steel wedge wire filter screen is a multifunctional screen with toughness and anti-clogging properties, in which slots/slots (screen holes) suitable for application are formed by arranging triangular "wedge wires" at equal intervals. They can be used for filtration, solid-liquid separation, classification, dehydration, concentration, etc., regardless of industry or geographic location.

01

Wedge wire

Features of Wedge Wire Screen:

1. Not easy to block, good dehydration effect: the biggest feature of the wedge-shaped wire mesh is "triangle", which means that when the solid passes through, the contact point is very small, and the tip of the slit widens, so the solid is less likely to block, even if they are not It will block and have a strong backwash effect, resulting in excellent maintainability.

2. High strength, strong and durable: Wedge-shaped wire mesh screens have higher strength and durability than filters such as wire mesh, perforated plates or filter cloths, and they can be used almost indefinitely according to the use environment and materials No replacement is needed, which reduces operating costs. In addition, we can also use special materials (such as titanium or duplex stainless steel) to produce wedge wire mesh.

3. Flexible design: Because of the variety of treatments, the wedge-shaped wire mesh can be made into various shapes, such as flat plate, cylindrical, cylindrical or conical.

In addition, the filter core made of wedge wire material can be widely used in various industries, such as petrochemical, medical, paper, sugar, wine, coal mine, water treatment, wastewater filtration, fishery, seawater desalination and other industries.