Metal mesh filter is a professional term for the filtration industry. Purification equipment is needed to purify the original ecological resources and the reuse of resources. Now metal mesh filters are mainly used in oil filtration, air filtration, water filtration, air filtration and other filtration industries. It is used to remove a small amount of solid particles in liquid or air, which can protect the normal operation of the equipment or clean the air. When the fluid enters the filter element with a certain size filter, its impurities are blocked, and the clean fluid flows out through the filter element. The metal mesh filter element allows the liquid (including oil, water, etc.) to clean the contaminated liquid to the state required for production and life, that is, to make the liquid reach a certain degree of cleanliness. Air cleans the polluted air to the state needed for production and life, that is, to make the air reach a certain degree of cleanliness.

Everyone knows that many things in our life need to be replaced when they are used for a long time, but some of them are replaced at a high or low frequency. As for metal mesh filter elements, the main reasons for frequent replacement of metal mesh filter elements are Which ones?

1. The quality of raw water is unstable and frequently fluctuates, which leads to too much particulate matter entering the metal mesh filter, resulting in shortened cycle. The pretreatment effect of the metal mesh filter element is poor. The flocculants and scale inhibitors added in the pretreatment are incompatible with each other or do not match the water source. The formed sticky substance adheres to the surface of the filter element, resulting in a decrease in the effective filtering area of the metal mesh filter element, causing The filter element is changed frequently. The quality of the metal mesh filter element is not good. The inner and outer pore diameters of the poor quality metal mesh filter element are basically the same. In fact, only the outer layer plays the role of interception. The good filter element pore diameter is gradually reduced from the outside to the inside. μm, the amount of pollution is larger and larger, and the long time used can also ensure that the effluent quality is qualified.

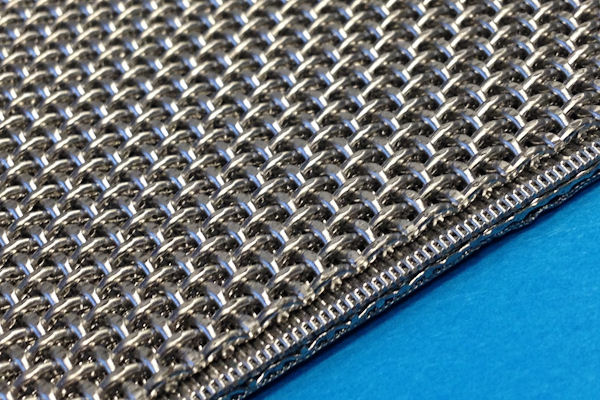

2. Through the re-examination of the metal mesh filter element, it has the characteristics of strong corrosion resistance, good permeability, high strength, convenient cleaning, high filtering accuracy, clean filter materials, and no silk screen peeling. It also has the advantages that ordinary steel wire mesh cannot match Such as high strength, good rigidity, stable grid shape, etc. Due to the reasonable matching and design of the space, permeability and strength characteristics of the material, it has good filtration accuracy, filtration resistance, mechanical strength, abrasion resistance, heat resistance and Processability and comprehensive performance are significantly better than other types of filter materials. The standard material of the metal mesh filter is 316L, the size is 1200 mm by 1000 mm by 1.7 mm, and the filtering accuracy is controlled at 2-300um. All metal mesh filters are produced All are carried out according to production standards and can be used for precision filtration of various hydraulic oils and lubricants in the machinery industry. Filtration and purification of various polymer melts in the chemical fiber membrane industry. Filtration of various high-temperature corrosive fluids in the petrochemical industry. Filtration, washing and drying of pharmaceutical industry materials. Homogenization of gases in the body industry. As a fluidizing plate for the steel industry. And splitting devices in explosion-proof electrical installations.

3. Five layer sintered mesh, also known as multilayer metal sintered mesh, is made of woven wire cloth with special lamination and vacuum sintering. It has high mechanical strength and overall steel. A new type of filter material. The meshes of each layer of wire mesh are staggered with each other, thereby forming a uniform and ideal filtering structure, which makes the material have advantages that ordinary metal wire mesh cannot match.

Five Layer Sintered Mesh

4. In the process of vacuum sintering of round hole metal filter screen, three obvious changes in vacuum degree are generally observed, that is, three times of a large amount of gas emission in the cemented carbide sintered body. The temperature at which the degree of vacuum changes for the first time is about 350 ° C. The main reasons are: first, the gas adsorbed on the particle surface is desorbed under the influence of temperature and negative pressure; second, the forming agent in the compact is volatilized in large quantities. The temperature at which the degree of vacuum changes for the second time is about 1100 ° C. The main reason for the significant change in vacuum is that the oxides in the compact are reduced by carbon (the reaction temperatures of WO3, TiO2 and C are 993 ° C and 1103 ° C, respectively). CO gas. The temperature of the sintered mesh filter element at the third vacuum degree change generally occurs at about 1350 ° C. At this time, the furnace temperature is above the eutectic temperature, and a liquid phase appears in the sintered body. In a vacuum state, the viscous liquid phase is prone to volatilization loss. Both physical and practical results show that the vacuum in the furnace is high, the sintering temperature is high, the sintering time is long, the content of the binder phase is high, the carbon content in the sintered body is high, and the volatilization loss of the binder phase is greater.