There are three cleaning methods for sintered mesh, namely: chemical cleaning method, stainless steel sintered mesh ultrasonic cleaning method, heat treatment cleaning method. First of all, for the chemical cleaning method, the common method is the acid-base cleaning solution cleaning method. The acid-base solution can clean the filter for collecting polyester knots.

Five-layer sintered mesh has the characteristics of large dirt holding capacity, high filtration accuracy, and slow pressure rise. The knotted felt has the characteristics of large dirt holding capacity, long replacement cycle, high temperature resistance, corrosion resistance, reusable cleaning, etc. More and more favored by our customers. From the perspective of production and efficiency, regular and irregular maintenance of the sintered metal fiber felt or the filter and filter element processed from it is obviously necessary. So how do you maintain it?

Heat treatment cleaning method, this kind of hair is generally used when the chemical cleaning method can not work. Common heat treatment cleaning methods include vacuum pyrolysis, heating oven, sintered felt. Liquefied beds and hot salt baths.

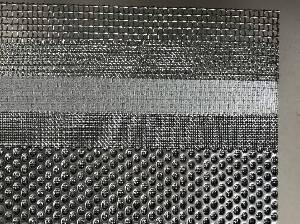

Five-Layer Sintered Mesh

The second is the ultrasonic sonic cleaning method. Ultrasound is a kind of wave energy that can be continuously pressurized and expanded. When it is applied to a liquid, cavitation can be generated, and continuously broken cavities can clean the sintered felt. The principle of sintered felt is the same as that of cleaning the sintered mesh with ultrasonic waves.

The specific cleaning method to be used for cleaning needs to be determined according to the company's own production conditions and the condition of the filtering equipment. It should be noted that after cleaning the stainless steel sintered mesh, a bubble point test is required to check its integrity And measure the pressure drop. We still remember to use stainless steel sintered mesh, friends who do not understand how to take care can contact our customer service.

Customers will have a set of methods for cleaning products, and the time taken is enough to show that this method works well.

Structure and characteristics of multi-layer stainless steel sintered mesh: five-layered sintered mesh: composed of protective layer, filter layer, separation layer and two-layer support layer; high strength, good rigidity: high mechanical strength and compressive strength. Excellent cleaning performance, good counter-current cleaning effect, can be used repeatedly, and sintered mesh makes it have excellent filtration accuracy and long filter life (can use counter-current water, impedance, mechanical strength, and processed filtrate, ultrasonic, dissolution, baking And other methods). Dispersed cooling material for high temperature environment: used for gas distribution, liquid bed orifice plate material, used for high precision, high reliability high temperature filter material, used for high pressure reaction; ten wash oil filter.