Filtration mechanism and characteristics of stainless steel sintered wire mesh

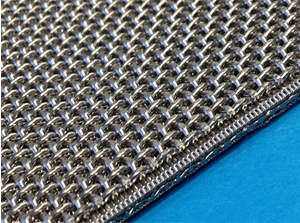

Sintered mesh is a commonly used filter material.

The stainless steel sintered mesh is pressed by a special laminate, which has high overall rigidity and mechanical strength. At the same time, the stainless steel sintered mesh is also a very good filtering material, and its comprehensive performance is obviously better than other similar products.

It has a good filtering mechanism in stainless steel sintered mesh. When the filter cake is mechanically filtered, many inclusions larger than the mesh size of the stainless steel sintered mesh are blocked at the entrance of the stainless steel sintered mesh. As the number of closed inclusions increases, a "filter cake" consisting of large inclusions is formed on the entrance surface of the stainless steel sintered mesh. The filter cake thins the flow so that inclusions smaller than the mesh size of the stainless steel sintered mesh are also partially captured on the "filter cake". Some non-floating slag can be blocked by stainless steel sintered mesh, and the blocked slag itself has a filtering function, that is, two-way filtering.

Adsorption mechanism: Stainless steel sintered mesh has a large specific surface area. The metal liquid flow is divided into a thin liquid flow unit through a stainless steel sintered mesh, which increases the contact area between the metal melt and the filter medium, harmful elements and oxidation in the metal melt. The complex physical and chemical reactions with the surface of the stainless steel sintered mesh are adsorbed on the surface of the filter, causing the inclusions to adhere to the filter frame layer by layer.

Five Layer Sintered Mesh

Characteristics of five layer sintered mesh

1. The stainless steel sintered mesh has good processing and assembly performance and is easy to use.

2. Uniform and stable precision: All filtering precisions can achieve uniform filtering performance, and the mesh will not change during use.

3. Stainless steel sintered mesh can be used in a wide range of environments: it can be used in the temperature environment of -200 ℃ ~ 600 ℃, and it can be filtered in acid and alkali environment.

4. Excellent cleaning performance: good counter-current cleaning effect, can be used repeatedly, and long service life (can be washed with counter-current water, filtrate, melting, baking, etc.).

Application fields of stainless steel sintered wire mesh:

1.Filtration of various hydraulic oils in the machinery industry;

2. Filtration and purification of various polymer melts in the chemical fiber membrane industry, filtration of various high temperature and corrosive liquids in the petrochemical industry, filtration, washing and drying of materials in the pharmaceutical industry;

3. Application of gas homogenization in powder industry, fluidization plate in steel industry;

4.Sound generators for explosion-proof appliances;

5.Used as dispersing material in high temperature environment;

6.Sintered stainless steel mesh for gas distribution, liquefied bed orifice material;

7. Used for high-precision, high-reliability high-temperature filter materials;

8.Used for high pressure backwash oil filter.