We are a screen mesh manufacturer. For more than 20 years' experience, we have accumulated technique and manufacturing experiences. And now we are serving customers from a wide range of industries from all over the world.

Sieve bend screen is mainly used in coal preparation plant and concentrator for pre dewatering, desliming, demineralization and grading slime recovery. It can also be used together with hydrocyclone to effectively grade, dewater, desliminate and demineralize fine materials. The screen machine is composed of a screen box with a 45 degree wrap angle and a 60 degree curvature radius of wi2030mm. Arc screen surface and screen frame adopt pivot structure, which can rotate 180 degrees and extend the service life of screen surface. The arc-shaped screen is turned from the feed box, screen box and screen machine base shaft to realize the position adjustment between the feed end and the discharge end, achieve uniform wear, extend the service life, and operate flexibly and conveniently. It has also been widely used in metallurgy, chemical industry and other industries.

Sieve Bend Screen

Working principle: the dewatering principle of the arc-shaped shale shaker is to separate the slime water by the cutting effect of the sharp edge on the feeding side of the screen bar; the arc-shaped screen is divided into the vibration arc-shaped screen and the non dynamic arc-shaped screen according to the difference between the use occasion and the moisture content of the material. HS arc screen is overturned by feed box, screen box and screen machine base shaft, realizing the position adjustment of feed end and discharge end, achieving uniform wear, prolonging applicable life and flexible and convenient operation. It has also been widely used in metallurgy, chemical industry and other industries.

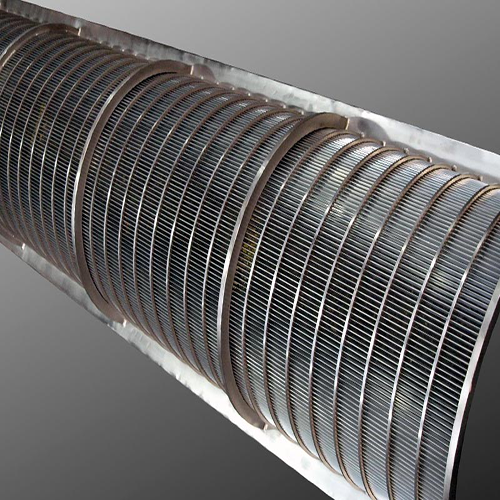

Multilayer sintered metal mesh is a new type of filter material with high mechanical strength and overall rigid structure, which is made of multilayer woven metal mesh by special lamination pressing and vacuum sintering processes. The mesh of each layer of wire mesh is staggered to form a uniform and ideal filtering structure, which not only overcomes the shortcomings of low strength, poor rigidity and unstable mesh shape of common wire mesh, but also can reasonably match and design the pore size, permeability and strength characteristics of materials.

Sintered Metal Mesh

Characteristic:

1. High strength and rigidity: it has high mechanical strength and compressive strength, good processing, welding and assembly performance, and easy to use.

2. Uniform and stable precision: uniform and consistent filtering performance can be achieved for all filtering precision, and the mesh hole does not change in use.

3. Wide application environment: it can be used for filtering in - 200 ℃ ~ 600 ℃ temperature environment and acid-base environment.

4. Excellent cleaning performance: the countercurrent cleaning effect is good, it can be used repeatedly and has a long service life (it can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking and other methods).