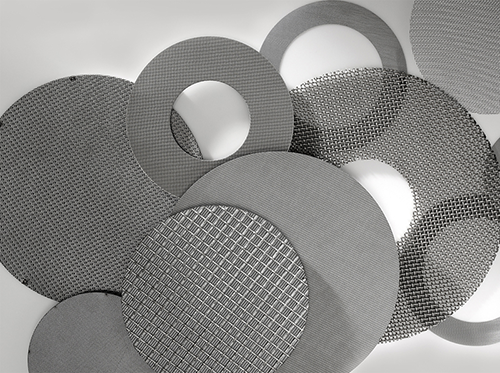

We are a wire screen supplier.Since the year 1998, we have noticed the need of the mesh filters and have set our aim as a leader manufacturer of the wire filter products.

The perforated wire mesh filter is a kind of precision equipment that directly intercepts the impurities in the water and oil, removes the suspended matters and particles in the water and oil, reduces the turbidity, purifies the water quality and oil quality, reduces the generation of system dirt, bacteria and algae, rust, etc., so as to purify the water quality, oil and other liquid bodies and protect the normal operation of other equipment in the system.

Working principle of mesh filter:

The water enters the mesh filter from the water inlet. First, the impurities of larger particles are filtered through the coarse filter element assembly, and then it reaches the fine filter screen. After the impurities of small particles are filtered through the fine filter screen, the clear water is discharged from the water outlet. In the process of self-cleaning filter filtration, the impurities in the inner layer of the fine filter screen gradually accumulate, forming a pressure difference between the inner and outer sides of the screen filter. When the pressure difference of the mesh filter reaches the preset value, the automatic cleaning process will start: the blowdown valve will be opened, the hydraulic motor chamber and hydraulic cylinder of the main assembly will release the pressure and discharge the water; the pressure in the hydraulic motor chamber and the suction pipe will be greatly reduced, because of the negative pressure of the mesh filter, the dirt on the inner wall of the fine filter screen will be sucked through the suction nozzle, and the water mesh filter force motor will flow into the hydraulic motor The chamber is discharged by the blowdown valve to form a suction process.

When the water flow of the mesh filter passes through the hydraulic motor, it drives the suction pipe to rotate, and the piston of the hydraulic cylinder drives the suction pipe to move axially. The suction device assembly cleans the inner surface of the whole mesh completely through the combination of the axial movement and the rotary movement. The whole cleaning process will last for tens of seconds. When the drain valve is closed at the end of cleaning, the increased water pressure will make the hydraulic cylinder piston return to its original position, and the mesh filter starts to prepare for the next flushing cycle. During the cleaning process, the normal filtering work of the filter is uninterrupted.