Product features

YMX Y strainers are designed to mechanically remove solids from flowing steam, gases or liquid piping systems with the use of a perforated or wire mesh straining screen, thus to protect the equipments. They Y Strainers have less debris holding capacity and higher pressure drops than basket strainers. And the Y strainers can be used in both horizontal and vertical pipe runs. They can also be fitted with a cleaning blow-off connection at the end of the branch end.

These Y Strainers are usually supplied in four materials: iron, carbon steel, bronze, or stainless steel. The Iron cast Y strainers are the most often used ones, because it costs the least, and has good corrosion resistance in many services.

The Y Strainers are provided with a variety of end connections, including threaded, flanged, and welded. Standard screens are provided for either steam service or WOG (water, oil, gas) service. Other screens are available on request also.

Features:

Ductile Iron Body & Cover

Fusion-Bonded Epoxy Coating Inside & Outside

Flanges Conform to ANSI B16.1

5mm Screen Hole Inlet

Material:

Body: Ductile Iron

Cover: Ductile Iron

Screen: Stainless Steel SS304

Bolts, Nuts & Washers: Stainless Steel SS304 (A2-70)

Paint: Fusion-Bonded Epoxy

Cast Y Strainers, Flanged Buttweld, RTJ

Size: 1/2″ thru 24″

End Connections: Flanged, Buttweld, RTJ

Body Materials: Cast Iron, Cast Ductile Iron, Cast Steel, Cast Stainless Steel, Cast LCC

Pressure Ratings:

Cast Iron: ASME Class 125

Cast Ductile Iron: ASME Class 250

Cast Steel: ASME Class 150 thru 1500

Cast Stainless Steel: ASME Class 150 thru 1500

Cast LCC: ASME Class 900 & 1500

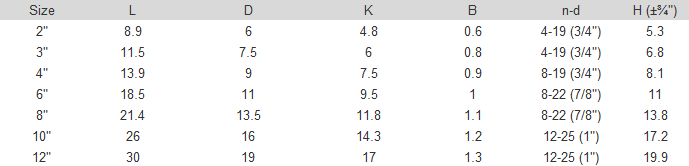

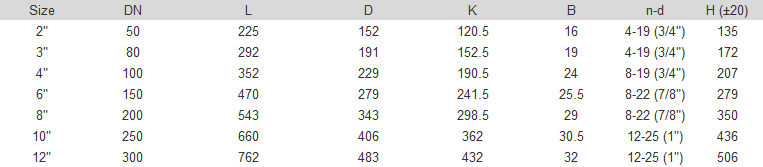

Product Parameter

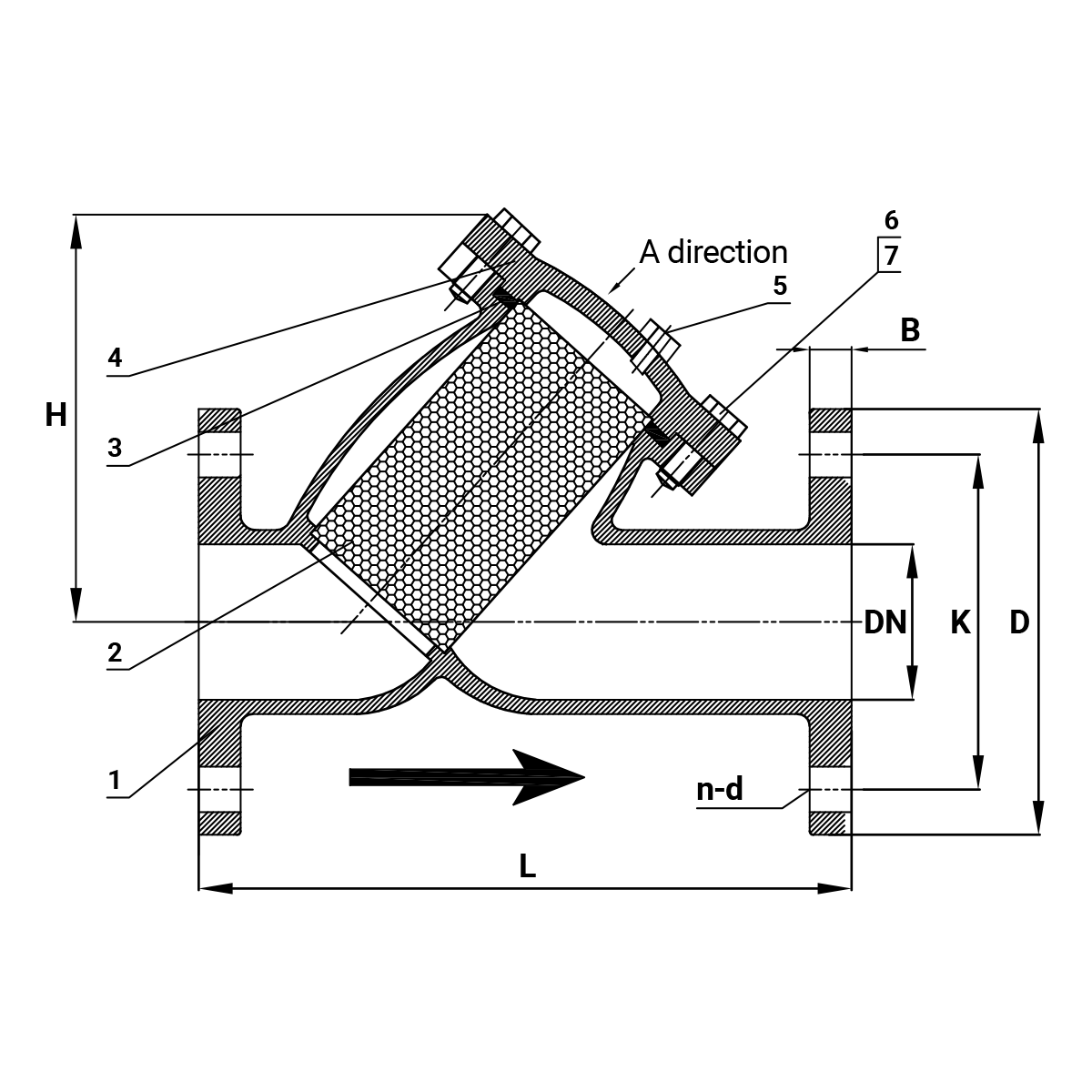

configuration