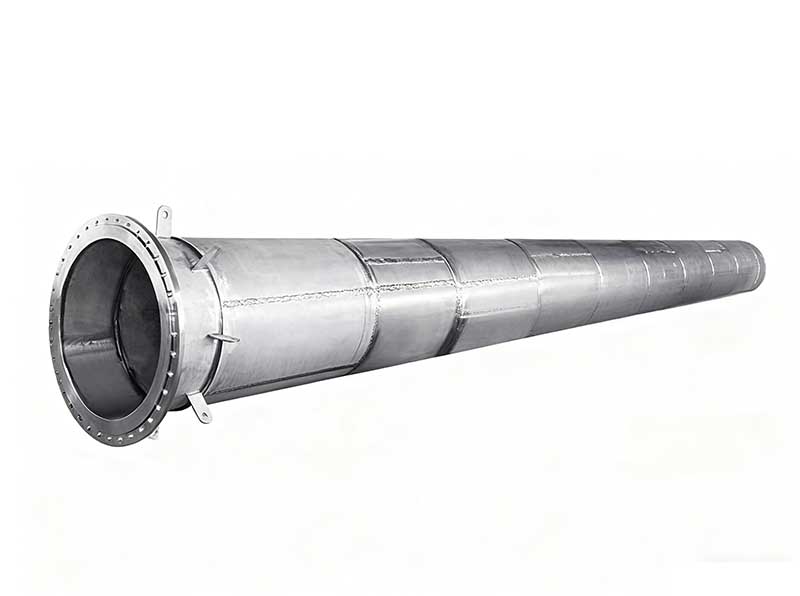

Wedge wire screen pipes are widely used in water and oil filtration systems due to their durability, precise slot design, and high efficiency in separating solids from liquids. These pipes are engineered to meet various industrial requirements, and different types are available depending on the application, fluid properties, and filtration needs.

Straight slot wedge wire screen pipes are the most common type used in water and oil filtration. They feature uniform V-shaped slots that allow liquid to pass through while retaining solids.

Applications:

Water intake screens for municipal and industrial water treatment

Oil well sand control and crude oil filtration

Cooling water systems in power plants and industrial facilities

Advantages:

High filtration accuracy

Low clogging risk due to V-shaped wire design

Durable and corrosion-resistant

Multi-layer wedge wire screen pipes consist of multiple layers of wedge wires or screens, often separated by support rods. This design improves strength and filtration precision for heavy-duty operations.

Applications:

Slurry separation in mining and mineral processing

Filtration of viscous oil or water with high solid content

Industrial wastewater treatment

Advantages:

Increased structural strength

Enhanced separation efficiency

Can handle high pressure and abrasive materials

Perforated wedge wire screen pipes combine a perforated base with wedge wire layers to provide high flow capacity with controlled filtration. They are often used when flow rate is critical without sacrificing separation quality.

Applications:

Oilfield filtration and sand control

Large-scale water filtration systems

Chemical and process industry fluid separation

Advantages:

High throughput

Improved structural stability

Suitable for large-diameter pipes and high-flow system

Some industrial applications require custom designs based on slot size, pipe diameter, material, or surface finish. Customized wedge wire screen pipes are tailored for specific water or oil filtration challenges, such as corrosive fluids, high temperatures, or fine particle separation.

Applications:

Desalination plants and seawater intake systems

Petrochemical and oil refining

Specialty water treatment and industrial processes

Advantages:

Optimal performance for specific fluids

Extended service life

Meets unique process requirements

Wedge wire screen pipes are typically made from:

Stainless Steel 304 / 316 – corrosion-resistant for water and mild oil

Nickel Alloys or Duplex Steel – for harsh chemical or oilfield environments

High-Strength Carbon Steel – when strength is prioritized over corrosion resistance

The V-shaped wedge wire is precision-welded onto supporting rods to maintain slot accuracy and structural integrity.

Wedge wire screen pipes are essential components for efficient water and oil filtration, offering precision separation, durability, and versatility. By selecting the right type—whether straight slot, multi-layer, perforated, or customized—industries can ensure high throughput, reduced maintenance, and reliable filtration performance in applications ranging from municipal water treatment to oilfield sand control.