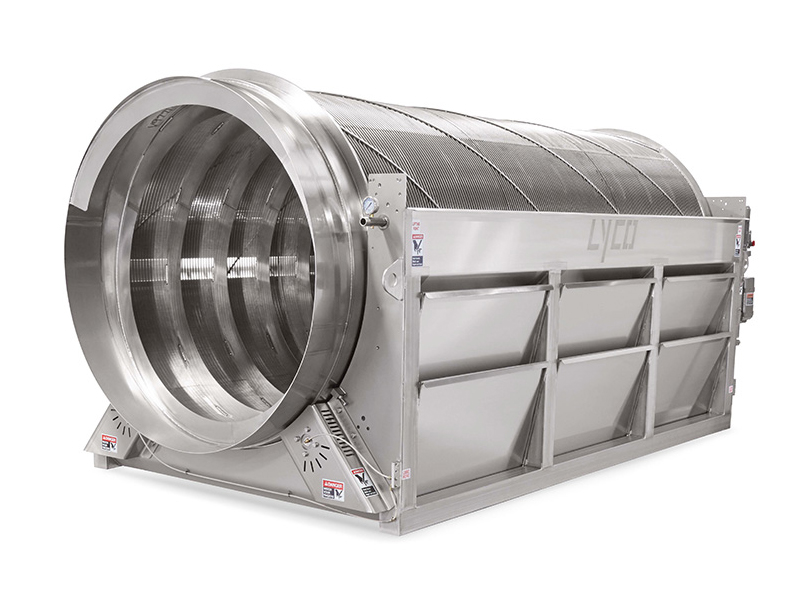

Industrial rotating drum screens are specialized equipment designed for efficient separation of liquids and solids in large-scale industrial processes. With their rotating cylindrical design, these screens provide continuous operation, high throughput, and reliable performance, making them essential in industries such as mining, chemical processing, wastewater treatment, food production, and agriculture.

Rotating drum screens consist of a cylindrical drum covered with perforated or wedge wire panels, mounted on a frame with a motorized rotation system. The separation process works as follows:

Bulk material, slurry, or wastewater is fed into the drum.

Liquids and fine solids pass through the perforations or slots in the rotating drum.

Larger solids are retained inside the drum and discharged at the drum’s end.

The drum’s continuous rotation prevents clogging, ensures high flow rates, and maintains efficient separation even with materials containing high solid content.

Rotating drum screens are widely used where high-capacity liquid-solid separation is required:

Mining & Mineral Processing: Dewatering slurry, separating ore from water, or processing sand and gravel.

Wastewater Treatment: Screening suspended solids, sludge, and debris before treatment.

Food Industry: Removing solid particles from liquids during beverage or food production.

Chemical Processing: Separating solid catalysts or byproducts from chemical liquids.

Agricultural Processing: Separating grains, seeds, or other bulk materials from liquids during washing or processing.

The design allows continuous, high-volume processing, which is crucial for industrial efficiency.

High Efficiency

Continuous rotation and precision slot/perforation design ensure accurate separation and high throughput.

Durable Construction

Made from stainless steel or corrosion-resistant alloys, suitable for abrasive and corrosive materials.

Low Maintenance

Rotating action prevents clogging, and the simple drum structure allows easy cleaning and inspection.

Versatility

Suitable for a wide range of liquids, slurries, and bulk materials, including high-solid-content mixtures.

Scalable Design

Can be manufactured in various diameters and lengths to meet specific process requirements.

Industrial rotating drum screens provide a reliable, efficient, and versatile solution for liquid-solid separation in industrial operations. Their continuous operation, robust construction, and adaptability make them suitable for mining, wastewater treatment, chemical processing, food, and agricultural applications. By integrating industrial rotating drum screens, operators can achieve higher throughput, improved separation efficiency, and reduced maintenance costs.