Sieve bend screens are a type of industrial screening equipment designed for separating solids from liquids or classifying materials by size. They are widely used in industries such as mining, chemical processing, water treatment, and mineral processing. Known for their durability and high efficiency, sieve bend screens are an essential component in modern material separation systems.

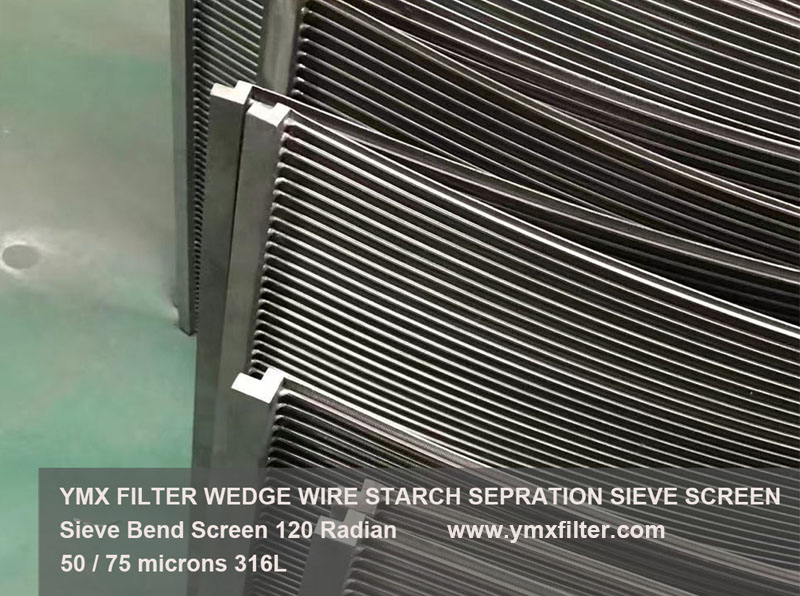

A sieve bend screen typically consists of a curved, wedge-shaped or perforated panel mounted on a support frame. The surface of the screen has slots, holes, or woven wire openings that allow liquids or fine particles to pass through while retaining larger solids.

The working principle is simple but effective:

Material enters the screen feed box or hopper.

Liquids and fine solids pass through the openings in the curved screen.

Larger solids move along the curved surface and are discharged at the end.

The curvature of the screen increases contact area, improves liquid drainage, and enhances separation efficiency, making sieve bend screens ideal for thick slurries or heavy solid-liquid mixtures.

Sieve bend screens are used in various industries where efficient separation of solids and liquids is required:

Mining & Mineral Processing: Separating ore, sand, and gravel in processing plants.

Water Treatment: Screening suspended solids from wastewater or sludge.

Chemical Industry: Filtering and classifying raw materials or process liquids.

Pulp & Paper Industry: Removing unwanted solids from paper pulp or slurries.

High Efficiency: Curved design ensures faster drainage and better separation of solids from liquids.

Durability: Constructed from stainless steel or wear-resistant alloys to handle abrasive slurries.

Low Maintenance: Reduced clogging due to smooth surface and self-cleaning action.

Versatility: Suitable for a wide range of materials and liquid viscosities.

Compact Design: Curved configuration allows for installation in limited spaces while maintaining high throughput.

Sieve bend screens are a reliable, high-performance solution for industries that require efficient solids-liquid separation. Their curved design, durability, and adaptability make them a preferred choice in mining, chemical processing, water treatment, and other industrial applications. By using sieve bend screens, operators can achieve higher efficiency, reduced maintenance, and improved process performance.