Wedge wire screens, also known as profile wire screens or V-wire screens, are essential components in modern industrial filtration systems. Widely used in water treatment, oil and gas, mining, chemical, and food processing industries, these screens offer precise filtration, high durability, and easy maintenance. In this article, we will explore the working principle, categories, and advantages of wedge wire screens.

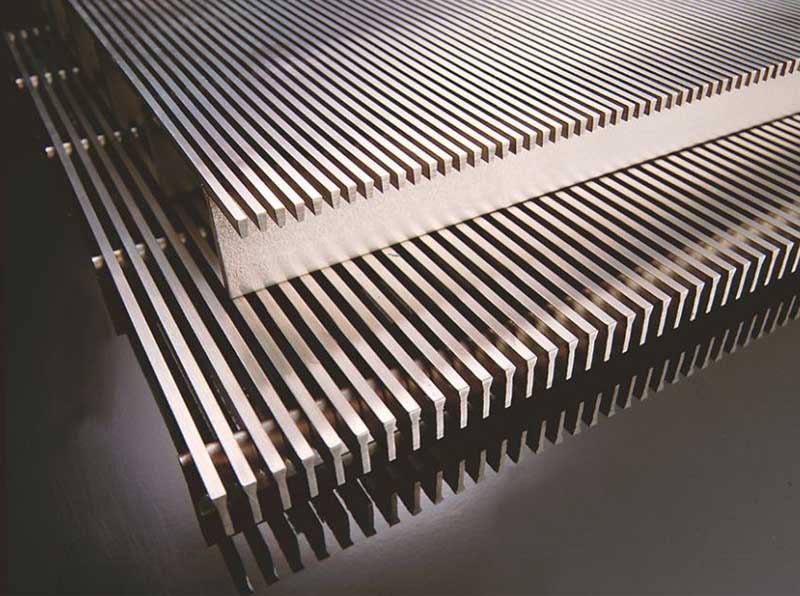

The wedge wire screen is constructed by welding V-shaped wires onto support rods, forming continuous slots with a precise and uniform width. This structure allows the screen to filter liquids and solids efficiently while maintaining high flow rates.

The working principle is straightforward: when liquid or slurry passes through the screen, particles larger than the slot width are retained, while smaller particles pass through. The V-shaped profile prevents clogging because debris is automatically guided outwards by the wedge shape, reducing pressure drop and maintenance requirements.

Common applications include:

Water intake screens in municipal or industrial water treatment

Slurry separation in mining operations

Well screens for groundwater extraction

Filtration in chemical or food processing lines

Wedge wire screens are available in multiple designs to meet different filtration requirements:

Cylindrical Wedge Wire Screens

Often used as well screens, filter tubes, or sand screens

Cylindrical shape allows high flow rate and uniform particle retention

Panel Wedge Wire Screens

Flat or rectangular panels used in liquid filtration tanks, sedimentation basins, or water treatment systems

Easy to install and maintain

Lateral Wedge Wire Screens

Common in water intake systems and pipe filtration

Designed for structural support and high flow efficiency

Customized Wedge Wire Screens

YMX Filter offers customized screens according to slot size, material, and shape requirements

Materials include stainless steel, carbon steel, nickel alloys, or other corrosion-resistant metals

Wedge wire screens are preferred in industrial filtration due to several key benefits:

High Precision Filtration

The uniform slot design ensures accurate separation of solids from liquids, reducing contamination and protecting downstream equipment.

Durability and Corrosion Resistance

Constructed from high-quality stainless steel or specialized alloys, wedge wire screens resist wear, corrosion, and chemical damage, even in harsh environments.

Self-Cleaning Function

The V-shaped design allows particles to move outward, minimizing clogging and reducing cleaning frequency.

Customizable Designs

Wedge wire screens can be tailored for slot width, shape, material, and size, making them suitable for diverse applications from water treatment to oilfield filtration.

High Flow Capacity and Low Maintenance

The precise geometry enables high flow rates while maintaining low pressure drop, reducing energy costs and operational maintenance.

Versatile Applications

Suitable for industrial filtration, water treatment, chemical processes, mining operations, and agricultural irrigation, providing a reliable and long-lasting filtration solution.

Wedge wire screens are highly efficient, durable, and versatile filtration solutions used across multiple industries. By understanding their working principle, categories, and advantages, industrial operators can select the right screen for specific filtration tasks, ensuring high performance, longevity, and cost-effective operation.

YMX Filter specializes in manufacturing high-quality wedge wire screens with custom designs to meet various industrial requirements. Whether for water treatment, mining, chemical processing, or food applications, their wedge wire screens provide reliable and precise filtration solutions.